Paperback/Softcover Binding Types

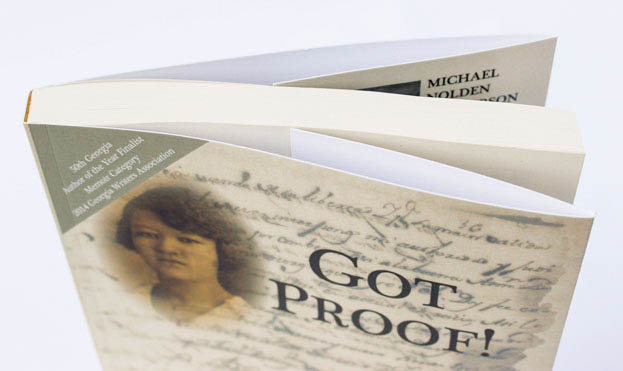

Perfect Binding

Pages are stacked and milled along the spine to improve the bond between the paper and the glue. An industrial glue is applied to the spine where the pages are then mated to a card-stock cover. The book is then trimmed on three sides to complete the “perfect” look where pages are flush with the cover. Perfect Binding is common with most fiction and non-fiction books and is widely used throughout the industry as it enables printing on the spine of a cover.

Perfect Binding with Flaps

Similar to regular perfect binding with an addition of flaps on the cover to create a “dust-jacket like” book in paperback format. Pages are stacked and milled along the spine to improve the bond between the paper and the glue. An industrial glue is applied to the spine where the pages are then mated to a card-stock cover.

The book is then trimmed on two sides to complete the “perfect” look on the top and bottom of the book, and the flaps are scored and folded inwards.

Perfect Binding with flaps is becoming a popular new format and offers a more elegant presentation to a softcover book. The flaps can have additional information about the book on them and serve as a bookmark.

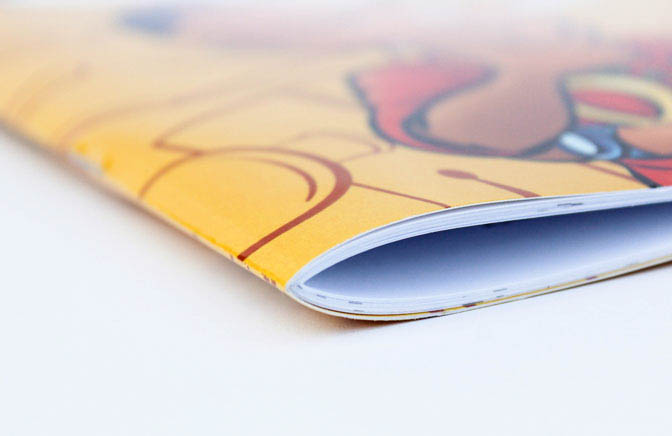

Saddle Stitched

Pages stapled in the middle to bind the pages together. They can also be “self-cover” where a cover stock is not used and the text itself is the cover of the book. Saddle Stitched books do not have a spine that can be printed on. Saddle Stitching is popular with children’s books, manuals, calendars, and other educational material. Saddle Stitching has a maximum binding tolerance of 60 pages depending on the weight (thickness) of the paper used.

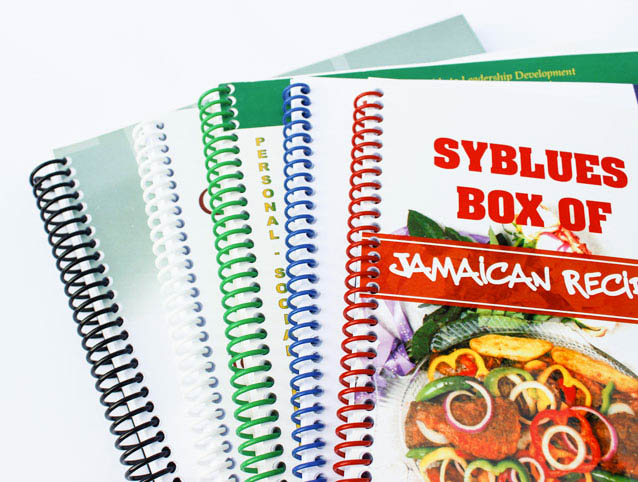

Plastic Coil/Spiral

Pages and covers are mechanically hole punched along the spine and a flexible plastic coil is then wound through the holes. Plastic coil is commonly used for manuals, workbooks, reports, and educational materials as it allows the book to easily open and lay flat. Plastic coil sizes vary depending on the amount of pages used and the thickness of the paper selected, however, they come at a minimum diameter of 6MM and a maximum of 50MM. Plastic coils are available in 45 different colors although not all colors are stocked as standard.

Wire-O/Metal Spiral

Wire-O books are produced similarly to plastic coil books in that pages and covers are mechanically punched along the spine. Wire-O then inserts a wire comb and is then “crimped” closed binding the book together. Wire-O’s applications are similar to plastic coil, manuals, workbooks, reports, and educational materials. Many cookbooks are also bound with this method. Wire-O is unique from plastic coil in that it allows a hard cover to be used for a more elegant look and increased durability. Wire-O has a maximum binding limitation of 250 pages depending on the weight (thickness) of the paper used.

Book Sizes

We can print your book in any standard size (such as 5.5×8.5″, 6×9″, 8.5×11″) or custom sizes. Typically the maximum size we can do is 11.5″ length x 12.5″ width. Please contact us if you have questions about a custom book size.

Not sure what size your book should be? We can show you a variety of samples to help you decide what size will best work for your manuscript.

Lamination Options

Choose from glossy or matte lamination for your book. Glossy lamination offers a high-shine/reflective look. Matte lamination has a sort of velvety feel and does not reflect light, a good option for products that will sit on store shelves.

Paper Options

Our papers handle text, graphics, black and white, and color work. We offer white and cream papers, and custom papers by request. A minimum order may apply for custom papers.

Paper limitations may apply for books being sold through our print on-demand service. See our print on-demand specifications for more.

Our staff can help you to select the right type of paper for your book.

Black/White and Color Printing

We can print your book in black/white, color, or a combination of the two. Color is an option that can enhance the look of your book. A popular choice is to print the pages of the book in black/white and have the cover in color.

Proof/ Sample Copy

As part of our setup and pre-press process we will create a finished copy of your book as a sample or “proof” to review.

Once we receive your files our pre-press and design team will meticulously review your files. Once they have reviewed and adjusted the files for print we will print, bind, and ship you a finished copy to review (or you can pick up the proof if you live in the Atlanta, GA area). This process has saved many authors time and money by enabling them to carefully go over the book one last time. We keep a copy for ourselves that we use as the standard for your book when it’s time to go to production.

Advanced Reading Copies

BookLogix can produce softcover books to be used as advanced reading copies and marketing books to be given or shipped to book reviewers, media, retailers, or distributors.